/Designed for those big areas

/The biggest of the 4 point systems

/Huge flying area of 285m x 285m

/Top Speed up to 15 m/s

/Completely weatherproof.

/WINCHES

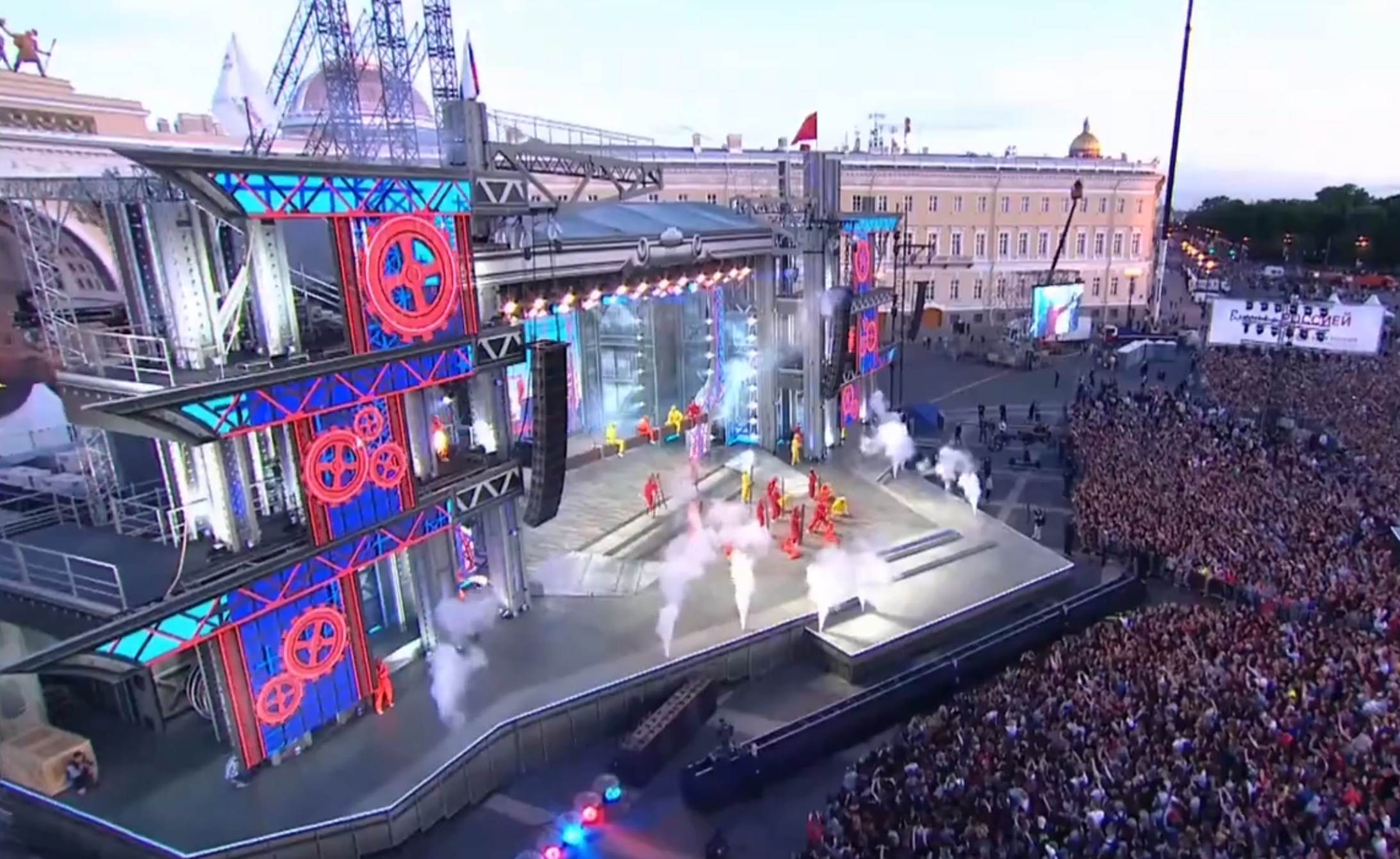

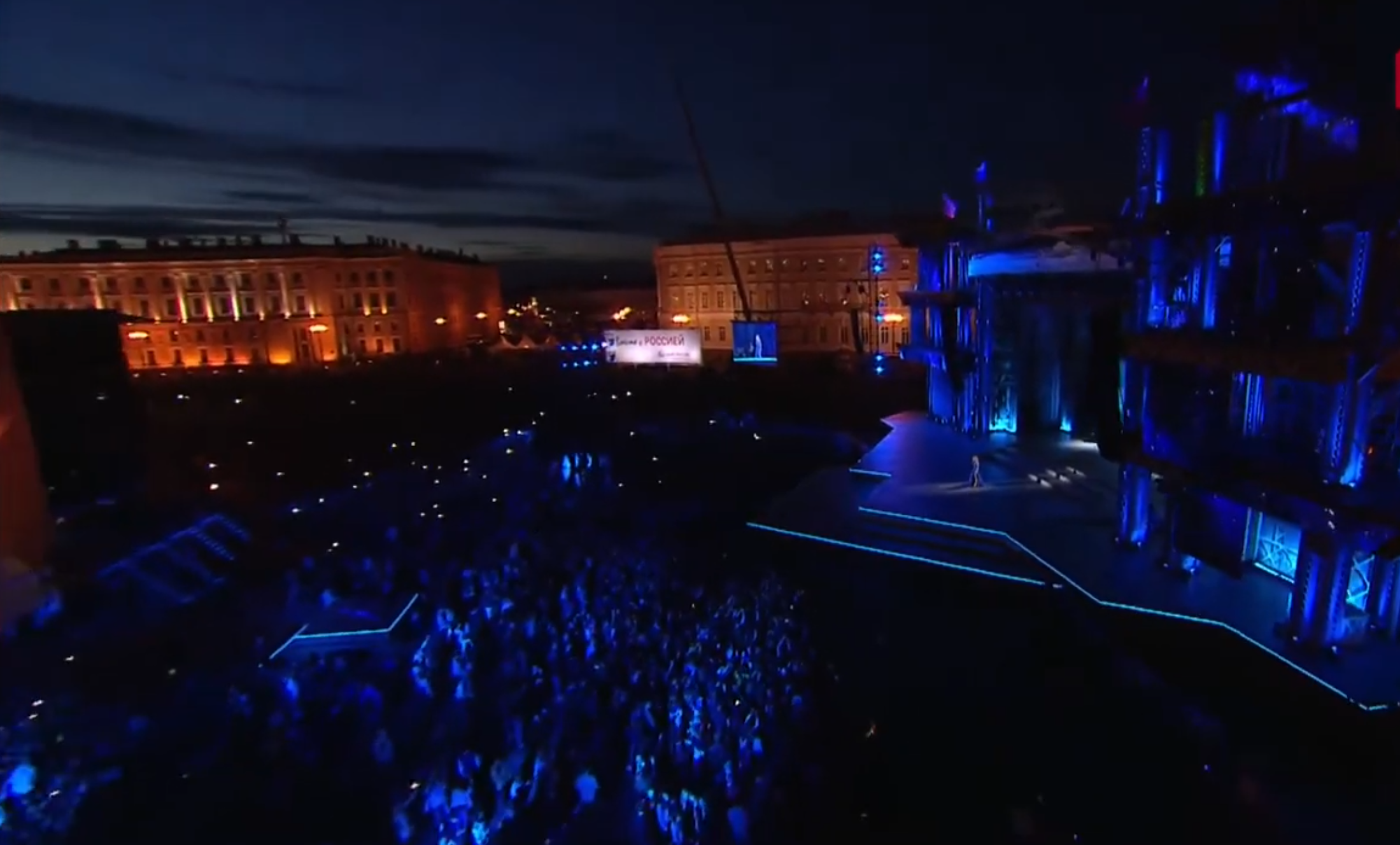

The largest of the 4 point camera systems with a maximum operating diagonal of 400m. Perfect to cover any big spaces with a peak speed of 15m/s and a 285m x 285m flight area.

/CONTROLS

The control station and winches communicate with each other via the cables. This allows interference free real time communication. the control station allows a single operator or a team to have complete control of all necessary system functions and controls.

/SMART

The software is the smarts of the system with multiple safety controls operating continuously to ensure the system is operating safely. You can have up to 300 memory presets in more than 30 locations. You can cut, edit and record about 450 paths of movement. This enables you to choose between different paths and initiate them quickly while creating a safe operating area. The flight accuracy of a programmed move is within 5 cm.

/GS200

The Industrial system does comes with the GS200 which is an integrated HD/4K camera with 3-axis stabilisation in a weatherproof & rugged carbon fibre case. It has full CCU Control with Genlock. A 20x (HD) or 18x (4K) optical zoom. Slip Rings for continuous rotation. IP control option. There is an option to use any broadcast camera up to 8kg.

/SETUP AND RIGGING

The camera is able to move about large spaces by changing the length on the various winches. The winches are ground mounted with the pulleys being rigged on either existing roof structures, light posts or cranes.

SPECIFICATIONS

Winch weight: 300kg

Power consumption: 31 kw - 400V 3 Phase

Max.operating diagonal: 400m (up to 600m)

Time to mount approx: 1 to 2 days

Payload: 30kg

Max camera weight: 8 kg

Max speed: 15 m/s

Size: 1150mm(W) x 1035mm(H) x 1060mmm (D)

Can withstand 9,500N of force for each of 4 cables – more than 12x the force occurring during normal operation

Retains most of its strength at temperatures ranging from -40°C to +100°C.

/CONTROLLER

The control station allows a single operator or a team of two to have complete control of all necessary system functions and controls.

Safety protocols operate in the background continuously to ensure the system is operating safely.

Up to 300 memory presets in more than 30 locations.

220V 1kW single phase power supply.

Height: 293mm

Diameter: 200mm

Weight: 5kg.

Power: 12 – 48v 30w (HD), 40w (4K)

Operating Temp: -10 to +40degC. Out of sunlight

Environmental: IP65 minimum

Pan Range: 360deg. Continuous.

Tilt Range: +/- 120deg from vertical.

Positional Accuracy: 0.0055deg.

HD Sensor: Panasonic 1/3 CMOS, 1944(H) x 1213 (V)

4K Sensor: Sony ½” CMOS, 3840(H) x 2160 (V)

Signal / Noise Ratio HD >50dB

Zoom HD: 20x optical

Zoom 4K: 18x optical

/Safety

The safety systems come first to provide a high level of confidence and consists of three phases.

First level (Software control):

There is programmable protection zones.

You program all of the controls, from joysticks to winches (reliability control).

Program control of power supply.

Program control of engine top power.

Second level (Operator control):

The operator can always stop the system by pressing the emergency button.

The operator can track any possible mistakes in the system on the computer.

Third level (Winch control):

All winches have magnet brakes, which stops them if the winch loses the signal.

If any cable is cut or unplugged during the operation, the system stops working.

If the computer fails, the system stops working.

The winches have set parameters for incoming power and stop if they exceed the set level.

After losing the signal or the power supply, the system won’t start again unless a safety check is done on all the winches.